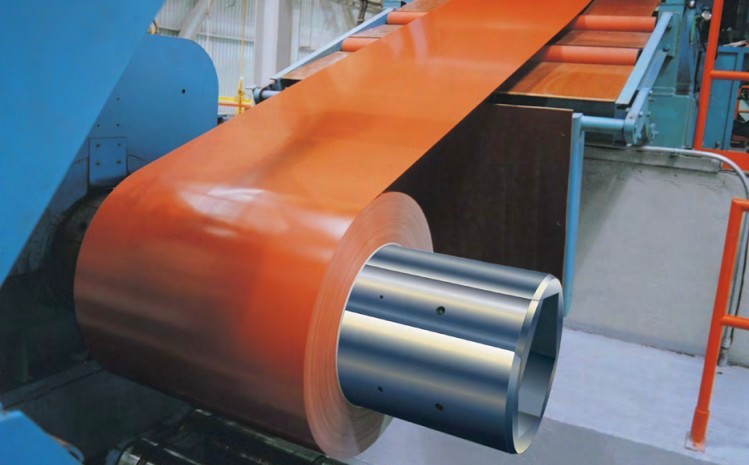

DELTA’s Paint Lines are custom-designed to deliver high-quality pre-coated coils to be used in the most critical applications. DELTA Paint Lines are designed to operate at speeds of up to 800 fpm (244 mpm) on material ranging from 0.008” (0.20mm) to 0.080” (2.0mm) thickness and 26” (660mm) to 72” (1830mm) width.

DELTA’s unique cleaning and chemical treatment sections are designed according to the application. Cleaning systems can be either electrolytic, high-pressure spray or brush scrubbing systems. In all cases, the rinse section is designed with sufficient dwell time to obtain the required results.

Our Paint Lines include such unique features as:

- MODULAR WATER TREATMENT

- FURNACES THAT EMPLOY INDIRECT FLAME TO AVOID DISCOLORATION OF THE WHITE PAINT

- ENERGY CONSERVING HEAT RECUPERATORS ARE USED TO PREHEAT THE STRIP AND IN THE DRYER OF THE CHEMICAL COATER

- CLOSED-LOOP CONTROLS IN THE PRIME AND FINISH OVENS

- STRIP QUENCHING WITH CLOSED-LOOP DEMINERALIZED WATER SYSTEM

- S-TYPE PRIME COATERS

- INTERCHANGEABLE COATERS THAT ALLOW CHANGING COLORS WITHOUT THE STRIP BEING STOPPED

Throughout the DELTA Paint Line, we implement strip guiding systems that maintain the strip centered in the line, thus the coiler produces a side wall that is either straight within ± 0.020” (± 0.5mm) or stagger wound per customer requirements.