DELTA’s Cut-to-Length (CTL) Lines are designed to produce the most accurate lengths and perfectly flat sheets or plates.

Our CTL products are the most proven in the industry. We have installed lines processing carbon steel, stainless steel, aluminum, copper and brass, and tin plate. We offer straight crosscut lines, multi-blanking lines, trapezoidal shearing lines and scrolling lines.

Our CTL products can be found on six continents in a variety of different types of plants: steel mills, metal service centers, automotive plants and original equipment manufacturer’s plants (OEM). Material from DELTA’s CTL lines is used in the food and beverage industry, electronics, and even in the world’s heaviest earth-moving equipment.

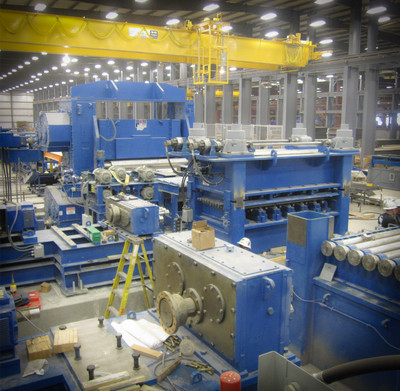

Our Heavy Plate Feed-to-Stop CTL Lines are designed to feed the strip material to a predetermined point beyond the shear, stop and then shear the strip to plate. Predominantly, feed-to-stop lines are “heavy gauge” lines ranging from 0.375” (9.5mm) — 1.00” (25mm) in thickness and 24” (610mm) — 120” (3050mm) in width. DELTA has more installed heavy gauge CTL’s than any other manufacturer in existence today. Our experience is unparalleled; we know what to do and what not to do.

In Looping Pit Lines, the material never stops in the entry section of the line. The shearing action occurs as the material is momentarily stopped after it is fed to a predetermined length beyond the shearing point by the feed rolls or a grip-feed system. The feeder system must accelerate to high velocities to maintain a constant average loop depth.

Continuous High Speed Cut-to-Length Lines are equipped with dynamic shears designed to cut the material at line speed, thus allowing the strip to move continuously. DELTA has revolutionized these types of lines with our DELTA Rotary Shear.